SBR Process & Operation:

SBR tank carries out the functions of equalization, aeration and sedimentation in a time sequence rather than in the conventional space sequence of continuous-flow systems. The SBR installation consists of at least two identically equipped tanks with a common inlet, which can be switched between them. In SBR,all related processes of Aeration, Settling, Decanting are carried out in same reactor which reduces construction cost against conventional system . The most important component of SBR process is decanting system. The various type of decanters are used for process like Moving arm, Floating , rake arm type, floating funnel type and slotted pipe type and Screw type decanters. The process is operated in batch manner and hence it is vary suitable for industrial wastewater and high flow domestic sewage wastewater. SBR is modern wastewater treatment system which involves use of automation in operation like PLC or SCADA.

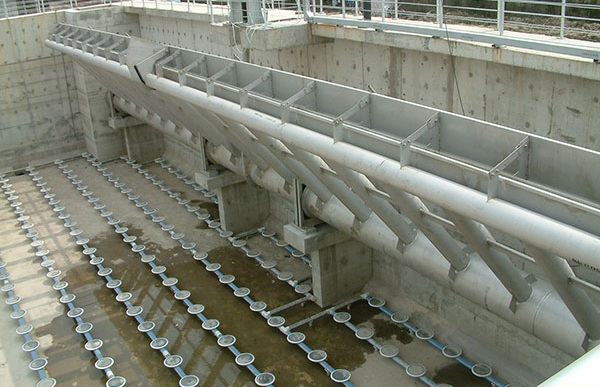

SBR Decanter:

Decanter is a key component of SBR process, it withdraws the treated effluent without disturbing the settled sludge layer. Our moving arm swing SBR decanter comes with a scum baffle driven by gear motor and actuator. We have a wide range of SBR decanter manufacturing capacity start from 0.5 mtr to 32 mtr weir length.

Features

• Moving arm type SBR Decanter

• Minimum Operating Cost

• Easy to operate and maintain

• Applicable for Batchwise and continues operation

• High & Stable performance

• Wide range from 1 MLD to 100 MLD